Pites Co., Ltd is one of leading agencies in industrial automation components and equipments for various industry such as Power Plant, Cement, Steel, Glass, Automation, Oil &Gas, Food and Berverage, Chemcial, Packaging, etc

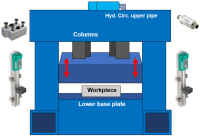

Modern fully electronic injection molding machines have to be tested regularly the nozzle touch force.

This applies, in particular, to ISO 9000 quality assurance.

The nozzle touch force sensor DAK measure the nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines reliably and reproducibly.

Simply place the DAK with the magnetic base onto the mold, connect it to our existing monitor and move the nozzle on to the sensor.

Then it can be measured immediately.

The sensor is made of hardened and tempered steel (corrosion-protected) and is therefore very solid and durable.

When using the DU-1D, DU-4D or DU-4USB monitors, make sure that the diameter of the sensor body is set on the monitor.

Only a properly adjusted diameter shows the measured force correctly in „kN“ and „t“.

Description

- Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines

- User-friendly, small and compact

- Force measurement range: 200kN / 450kN

- Very high repeatability

- Direct connection to our signal amplifiers and monitors

- Various nozzle adapters can be retrofitted (e.g., brass)

- Magnetic bases can be retrofitted in different sizes